LIGHTNING PROTECTION SYSTEM

The task of a Lightning Protection System (LPS) is to intercept all lightning

strikes entering a building, divert it towards the earth and distributed

in the earth. All metallic installations in the building shall be

made at equal potential in order to avoid dangerous flashover and

fire from the lightning current flowing through the LPS. The idea is to

prevent thermal, mechanical and electrical effects that can damage

the building to be protected, or humans through contact or

step voltages inside the building.

An external LPS is intended to:

- Intercept a lightning flash to the structure (with an air-termination system).

- Conduct the lightning current safely towards earth (using a down-conductor system).

- Disperse the lightning current into the earth (using an earth-termination system).

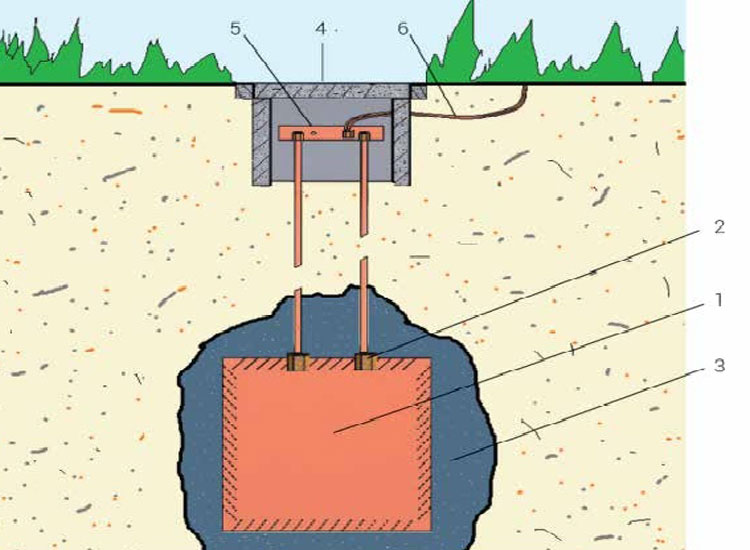

EARTH INSPECTION CHAMBER

Concrete earth inspection chamber is available in various sizes. Concrete chamber are heavy duty and can handle heavy truck loads.

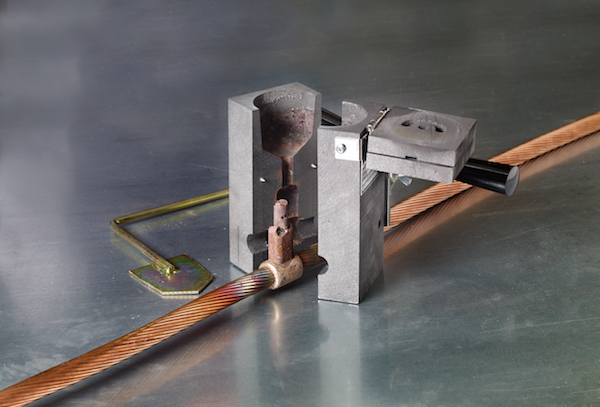

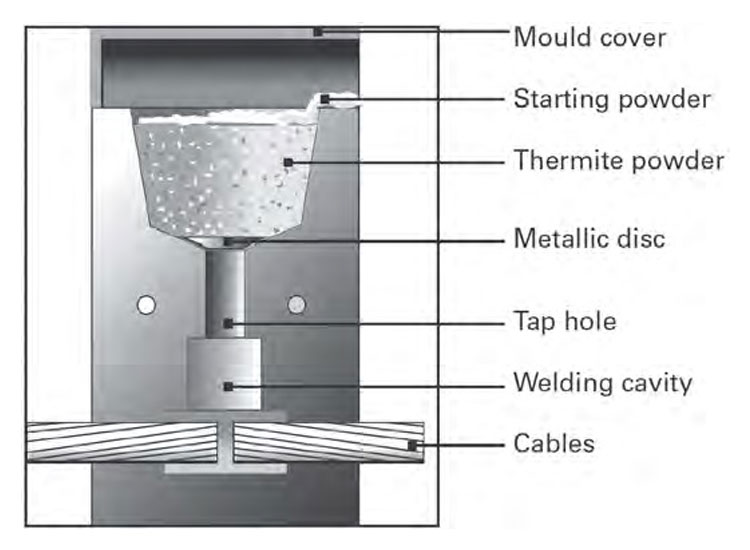

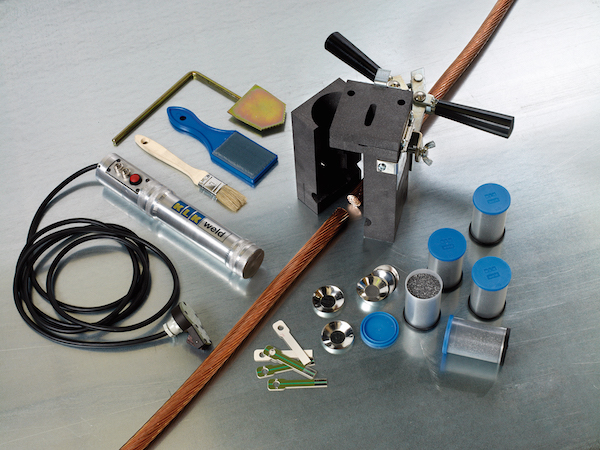

EXOTHERMIC WELDING SYSTEM

Exothermic welding connections are used widely in Earthing, Equipotential Bonding and Railway Applications. This weld process utilize the high temperature of the reaction between copper oxide and aluminium. The reaction happens in a graphite mould crucible, into which the pieces to be welded have been inserted. The molten metal from the exothermic reaction flows over the piece causing them to melt and fuse into a solid homogeneous mass.

An exothermic weld has higher mechanical strength than other forms of weld, and excellent corrosion resistance, It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation

PLATE EARTHING SYSTEM

Copper Plate Electrodes with connecting Wires are confirming to NBC-2016, UL as well as several national / international standards. These maintenance free plate electrodes offers long life. Electrode as well as conductors are made of high conductivity, non corrosive copper, exothermically welded to copper conductor in order to offer maximum life. Two meter long,two runs of connecting wires ensure deep burying of the plates in soil. Plate Electrodes of other sizes are available on request.

- 600 * 600 * 1.5 mm copper plate

2. Exothermic Welding

3. Earth Enhancement Material

4. Earth Chamber

5. BUS BAR

6. 70 Sq.mm Multi stranded copper wire

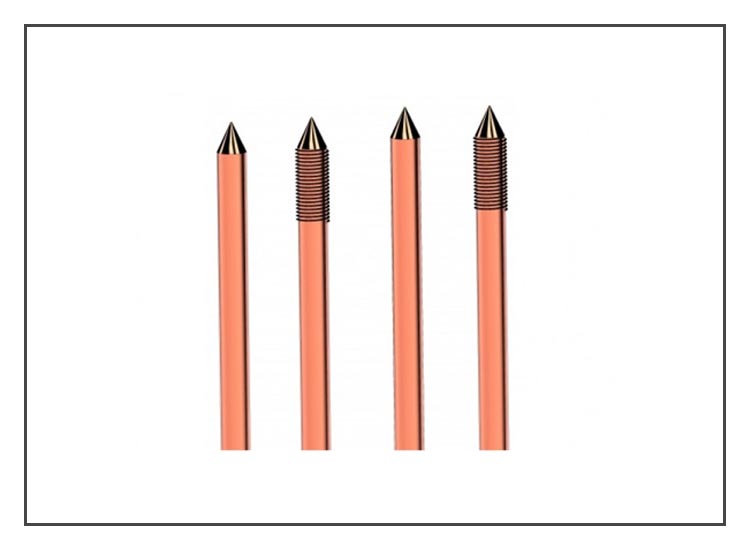

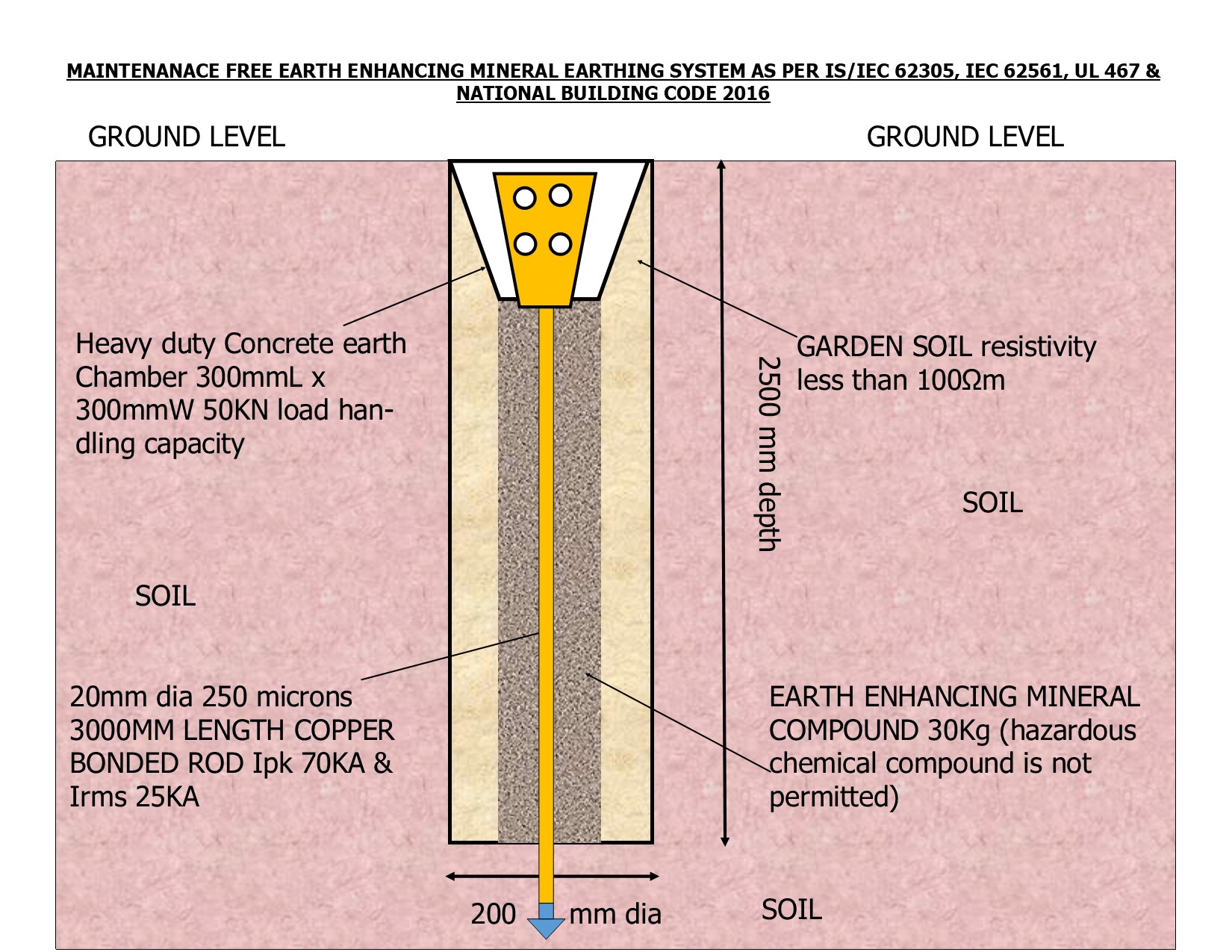

ROD EARTHING SYSTEM

The Rod earthing is basically non – treatment earthing. A copper rod of 12.5mm (1/2 inch) diameter or 16mm (0.6in) diameter of galvanized steel or hollow section 25mm (1inch) of GI pipe of length above 2.5m (8.2 ft) are buried upright in the earth manually or with the help of a pneumatic hammer. The length of embedded electrodes in the soil reduces earth resistance to a desired value.

- 600 * 600 * 1.5 mm copper plate

2. Exothermic Welding

3. Earth Enhancement Material

4. Earth Chamber

5. BUS BAR

6. 70 Sq.mm Multi stranded copper wire

PRO-CEM

Earth Enhancing Mineral Compound

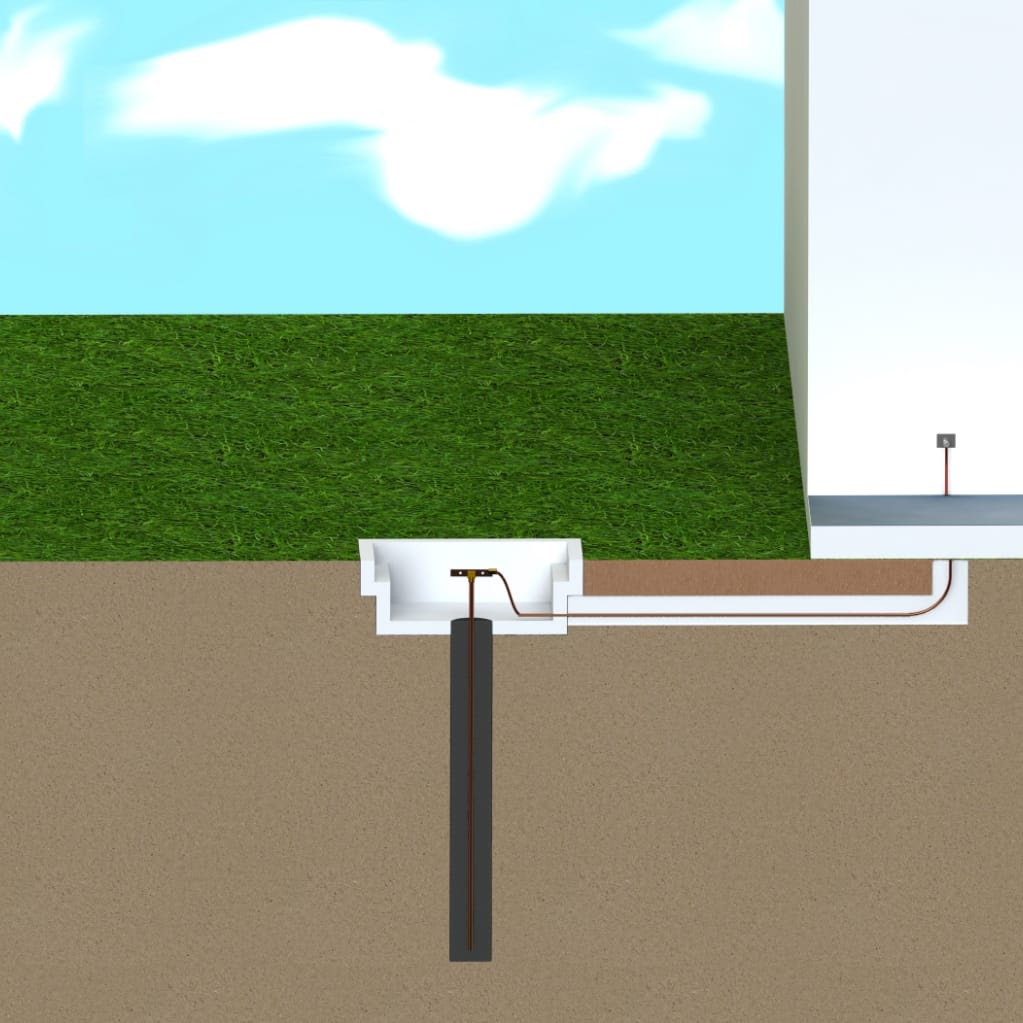

STRUCTURAL EARTHING SYSTEM

Foundation earthing is done using metal components used in construction of the building. Foundation earthing serves the purpose like safety, functional and lightning protection. This is the most efficient earthing system to protect electronic equipment. Interconnected steel-reinforcement, metal framework of structure, steel roof, metal façade, hand rails etc can be used as parts of an LPS such as air termination, down conductor and earthing. Materials used and construction techniques availed must fulfil various mechanical, electrical and chemical requirements to provide long life for the installation.

This integrated method is not only economical but does not influence or spoil the aesthetics of the building. It also reduces the failure of electronic equipment inside the building from radiated lightning effects.

Structural Bonding networks are important for modern buildings with sensitive electronic installations. Structural bonding networks ensure reduction in conductor loops and are significant in providing protection for electronics.

STRUCTURAL BONDING NETWORK is the economical and efficient way of achieving Earthing and Bonding requirement of modern electronic installations. As a standard practice IS 62305 as well as draft IS 732 recommends and allows to use these modern construction methods in new buildings